In 1996, we were engaged by the Greenhouse Challenge Office (now the Australian Greenhouse Office), the Minerals Council of Australia and the Australian Coal Association to produce a workbook for the minerals industry. The engagement was with Colin Randall (of C Randall & Associates) and Peter Stewart (of Molino Stewart) and the task was to produce a comprehensive workbook to assist industry members join and participate in the Greenhouse Challenge Program.

The workbook was completed in late 1996 and workshops held for the industry in NSW, Vic, SA, Qld, NT, and WA in early 1997. Feedback from the workshops indicated that the workbook had been favourably received. Copies of the workbook may be obtained from the Minerals Council State offices though the multipliers used in the calculations would need to be updated from the AGO web site.

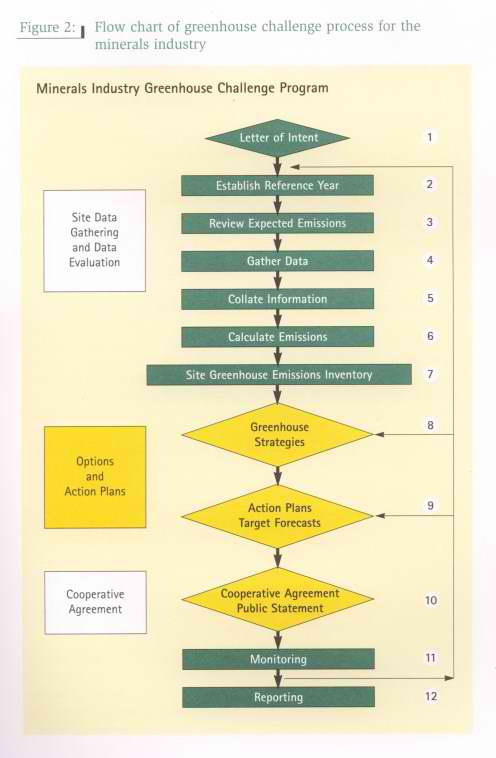

The workbook contains generic greenhouse gas abatement projects relevant to the industry, a flow chart of the steps in the Challenge Programme and spreadsheets to get you started.

The Greenhouse Challenge Programme is a voluntary program between the Commonwealth Government and industry. Participants agree to:

establish an emissions inventory of greenhouse gases that result from their activities,

monitor and manage those emissions,

set greenhouse gas emissions targets (may be total or per unit targets),

identify projects to reduce greenhouse emissions,

implement projects that are economically viable,

monitor the results against targets, and

report annually to the Australian Greenhouse Office (AGO),

issue a public statement about their progress with the program.

The various components of the programme to meet these requirements are:

An emissions inventory for the base year (starting year) and emissions projections for future years – say the next five years.

The emissions inventory should be established for each site, then aggregated across the group.

Greenhouse Strategies and Projects for each mine site in the group,

Greenhouse Gas Emissions Abatement Action Plans (for each site), including the possibility of group wise Actions (policy/awareness/purchasing),

An initial Public Statement on commitments in the cooperative agreement.

Monitoring (internal at each site, plus overall review across the group),

Project Implementation,

Project review and identification of new projects, and

Annual Reporting to AGO.

The flowchart pictured shows the steps in the program.

| Energy Management | |

| 1 | Energy Audit |

| 2 | Energy Management Program |

| 3 | Energy Monitoring as a Management a Tool |

| Energy Projects | |

| 4 | Air Compressors and compressed air systems |

| 5 | Bathhouse heating systems |

| 6 | Boiler Controls Steam Systems |

| 7 | Building Air Conditioning and Space Heating |

| 8 | Buildings – Insulation and Shade |

| 9 | Collect methane and use to generate electricity |

| 10 | Combined Heat and Power (Cogeneration) |

| 11 | Computerised Energy Management System |

| 12 | Drive Belts and Coupling Systems |

| 13 | Fuel Efficient Diesel Engines |

| 14 | Fuel Substitution: electricity instead of diesel |

| 15 | Fuel Substitution: LPG/CNG instead of diesel |

| 16 | Furnace Controls and Improvements |

| 17 | Heat Pumps |

| 18 | Heat Recovery |

| 19 | High Efficiency Electric Motors |

| 20 | Lighting Systems |

| 21 | Optimisation of Face Shovel and Dragline Performance |

| 22 | Remote Area Power Supplied Photovoltaic Panels |

| 23 | Solar Water Heating |

| 24 | Trolley Wire Assist for Haulage Trucks |

| 25 | Variable Speed Drives for Pumps |

| 26 | Variable Speed Drives for Fans |

| 27 | Ventilation Systems |

| Chemical Processes | |

| 28 | Energy efficient metallurgical processes |

| 29 | Fine Grinding Technology |

| 30 | Flare methane |

| 31 | Oil Reclamation System |

| 32 | Substitution of Chemicals in Recovery Process |

| 33 | Water Management |

| Mining Processes | |

| 34 | Alternative Transport Overland Conveyors |

| 35 | Codisposal of Fines |

| 36 | Larger trucks shovels graders |

| 37 | Minimise blasting of coal – Use hydraulic backhoe |

| 38 | Recover coal to reduce spontaneous combustion/improve recovery of resource |

| 39 | Reduced weight of dragline and shovel buckets |

| Explosives | |

| 40 | Blast Management |

| Training | |

| 41 | Teach staff to identify ways to improve energy efficiency |

| Environmental | |

| 42 | Clearing vegetation from areas to be inundated by dams |

| 43 | Tree plantings/Revised rehabilitation programs |

| 44 | Alternative feeds for agricultural animals |